Overview

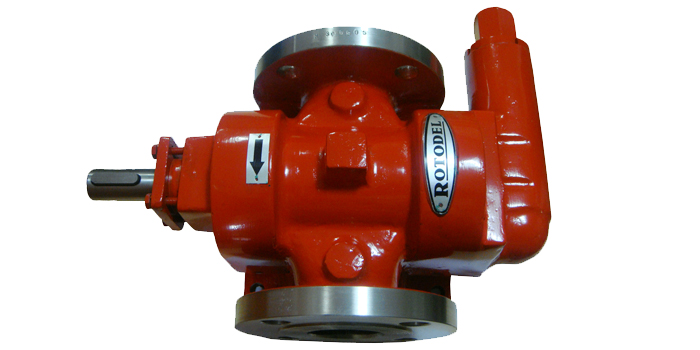

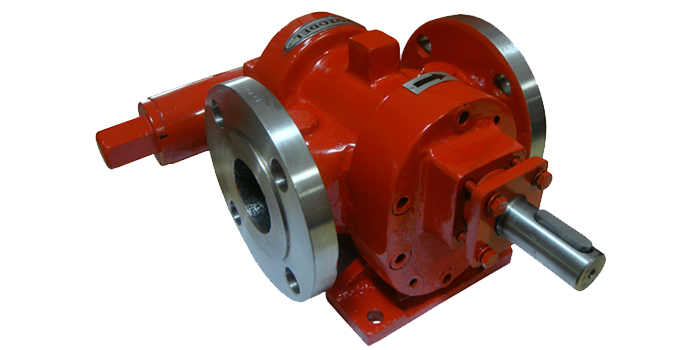

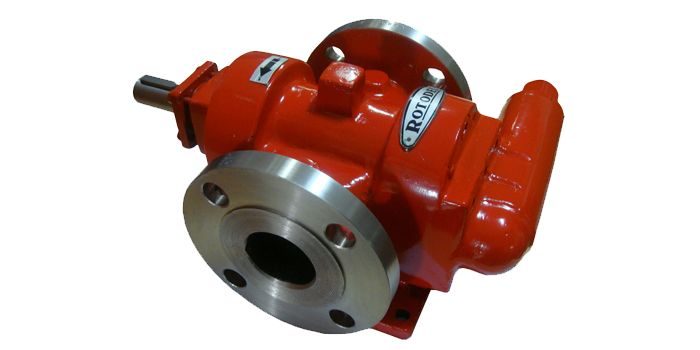

Self lubricated bish bearing design ROTARY GEAR PUMP type ‘RDMS’ for Foam-pressurizing fire fighting, Chemicals and Pharmaceutical applications & transfer of all kind of Viscous, Non viscous Thick or Thin liquids.

General

ROTODEL Rotary gear pump type RDMS is all SS, simple four piece construction pump specially designed to handle thinner or thicker & even corrosive liquid having lesser or no lubricating value. The SS-316 herring bone Rotors runs on Teflon coated dry running DU bush bearing supported on bronze wearing plate, placed inside the pump casing, alternatively graphite/bronze wearing plate cum bushes are also provided for heavier viscous liquid application. The stuffing box is fitted with Z-pack sealant with provision to fit mechanical shaft Seal. The pump is provided with add-on type pressure relief valve.

- Pump Body CF8

- Front Cover CF8

- Back Cover CF8

- Gland Cover CF8

- Rotar Gear SS-316

- Stator Gear SS-316

- Rotar Shaft EN-57/SS-430

- Stator Shaft EN-57/SS-430

- W.Plate – Bronze/Graphite

- Bushes Teflon Coated DU

- Shaft Seal – Z Pack/Mech. Seal

- Key SS-316

The Hydraulic HP should be calculated by multiplying the unit HP with the duty point pressure, the viscous horse power of appropriate viscosity should be added to this from above chart. Margin for R.V. operation & Safety margin should be provided brfore fixing the drive HP. All model of RDMS series are basically design to run at 1440 RPM up to viscosity of 200 CST however in higher sizes above 2″ the pump speed is required to be reduced with increase in viscosity for this refer viscosity speed curve or consult the works. Whir reducing the speed, the pump shaft should not be loaded with heavy gears or pulley use bearing block to take up such load.

Pump Model - Size - Capacity & Power Chart

| Pump Model |

Capacity at 1440 RPM |

Power REQ. | WT of Bare Pump p.set in KG |

||||||

|---|---|---|---|---|---|---|---|---|---|

| Port Size ASA-150 |

No Load Viscous h.p. |

Unit HP/KG Pres. |

|||||||

| LPM | US GPM |

M3/hr | 200 CST | 500 CST | 750 CST | ||||

| RDMS-050 1/2″ NB |

S | 13.0 | 3.30 | 0.75 | .075 | 0.11 | 0.19 | 0.034 | 8.5 |

| M | 16.6 | 4.40 | 1.00 | 0.10 | 0.15 | 0.25 | 0.045 | ||

| RDMS-100 1″ NB |

S | 30.0 | 7.92 | 1.80 | 0.16 | 0.28 | 0.40 | 0.088 | 9 |

| M | 37.5 | 9.90 | 2.25 | 0.20 | 0.35 | 0.50 | 0.110 | ||

| RDMS-150 1 1/2″ NB |

S | 60.0 | 15.8 | 3.60 | 0.32 | 0.52 | 0.60 | 0.176 | 12.0 |

| M | 75.0 | 19.8 | 4.50 | 0.40 | 0.65 | 0.75 | 0.220 | ||

| RDMS-200 2″ NB |

S | 100 | 26.4 | 6.00 | 0.40 | 0.68 | 0.80 | 0.272 | 22.0 |

| M | 125 | 33.0 | 7.50 | 0.50 | 0.85 | 1.00 | 0.340 | ||

| RDMS-250 2 1/2″ NB |

S | 150 | 40.0 | 9.00 | 0.71 | 0.94 | 1.13 | 0.405 | 28.0 |

| M | 200 | 52.9 | 12.00 | 0.95 | 1.25 | 1.50 | 0.540 | ||

| RDMS-300 3″ NB |

S | 250 | 66.0 | 15.00 | 0.94 | 1.28 | 1.50 | 0.615 | 40.0 |

| M | 333 | 88.0 | 20.00 | 1.25 | 1.70 | 2.00 | 0.820 | ||

| RDMS-400 4″ NB |

S | 415 | 111 | 25.00 | 2.92 | 4.17 | 5.00 | 1.100 | 68.0 |

| M | 500 | 132.9 | 30.00 | 3.50 | 5.00 | 6.00 | 1.320 | ||

| RDMS-500 5″ NB |

S | 600 | 158 | 36.00 | 4.00 | 6.00 | 7.20 | 1.568 | 110.0 |

| M | 750 | 197.5 | 45.00 | 5.00 | 7.50 | 9.00 | 1.960 | ||

| RDMS-600 6″ NB |

S | 1000 | 2630 | 60.00 | 5.63 | 7.50 | 9.00 | 2.700 | 170.0 |

| M | 1335 | 351 | 80.00 | 7.50 | 10.0 | 12.00 | 3.600 | ||

| RDMS-600 6″ NB |

S | 1611 | 451 | 100.0 | 10.0 | 12.5 | 15.0 | 3.988 | 200.0 |

| M | 2050 | 542 | 120.0 | 12.0 | 15.0 | 18.0 | 4.750 | ||

| Pump Model |

Pump Dimensions | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Overall | Mounting | Shaft | ||||||||||||||||

| A | F | V | H2 G |

B | C | E | D1 | D2 D3 |

D4 | T | D | H | H1 | L | L1 | P | Q | |

| RDMS-050 1/2″ NB |

215 | 150 | 35 | 130 – |

80 | 100 | 75 | 89 | 1/2″ | 08 | 10 | 12 | 80 | 69 | 26 | 38 | 04 | 13 |

| RDMS-100 1″ NB |

251 | 160 | 45 | 135 – |

90 | 110 | 91 | 108 | 1″ | 10 | 10 | 15 | 90 | 74 | 29 | 38 | 05 | 18 |

| RDMS-150 1 1/2″ NB |

295 | 180 | 52.5 | 160 – |

105 | 130 | 103 | 127 | 1.1/2″ | 10 | 10 | 21 | 100 | 80 | 34 | 45 | 06 | 24 |

| RDMS-200 2″ NB |

334 | 200 | 60 | 170 – |

110 | 150 | 117 | 152 | 2″ | 12 | 14 | 24 | 112 | 89.5 | 30 | 55 | 06 | 27 |

| RDMS-250 2 1/2″ NB |

369 | 220 | 60 | 200 56 |

130 | 160 | 140 | 178 | 2 1/2″ | 15 | 15 | 28 | 132 | 106 | 40 | 65 | 08 | 31 |

| RDMS-300 3″ NB |

453 | 235 | 75 | 241 56 |

160 | 220 | 161 | 190.5 | 3″ | 19 | 25 | 32 | 160 | 131 | 55 | 75 | 10 | 37 |

| RDMS-400 4″ NB |

525 | 275 | 90 | 270 66 |

180 | 270 | 171 | 228 | 4″ | 19 | 25 | 36 | 180 | 145 | 50 | 85 | 10 | 41 |

| RDMS-500 5″ NB |

600 | 300 | 90 | 305 66 |

200 | 280 | 200 | 254 | 4.1/2″ | 19 | 25 | 45 | 200 | 160 | 65 | 100 | 14 | 52 |

| RDMS-600 6″ NB |

663 | 340 | 90 | 345 76 |

220 | 350 | 216 | 279 | 5″ | 22 | 25 | 50 | 225 | 179 | 70 | 120 | 14 | 57 |

| RDMS-600 6″ NB |

710 | 356 | 100 | 360 76 |

240 | 380 | 244 | 343 | 6″ | 22 | 28 | 55 | 250 | 200 | 90 | 130 | 16 | 58 |

Uses

RDMS Pumps are used for handling thinner liquid at moderate pressurizing viz. foam pressurizing application for fire fighting, high pressure coolant transfer application for machine tools, light fuel pressurizing application or boiler & burners, heavy viscous liquid transfer application such as Molasses, Magma, Soap stock, Tar, Bitumen, Paints, Varnish, Crude oil etc.