Overview

for handling corrosive, abbrasive, hygienic viscous liquid for transfer, loading-unloading & pressurising applications.

- Efficient

- Reliable

- Proven

- Compact

Description

Handling high volume of viscous liquid at medium pressure is a challenge & calls for expertise. We at DEL have aquired this over last 25 years through in house research & development based on customer feed back & field trials.

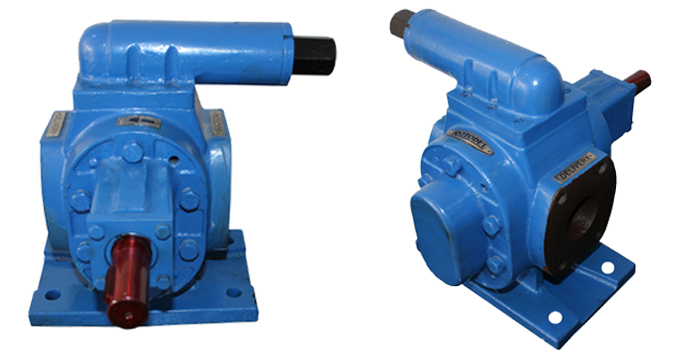

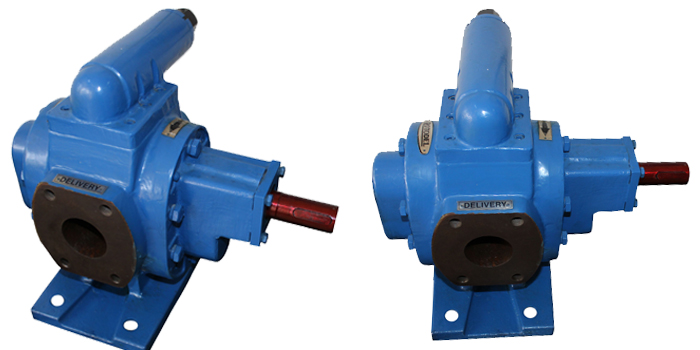

The proven range of rotary twin gear pump type ‘RDRN’ have been modified to achieve high pressure by reducing the bearing span, balancing the hydraulic force & blocking the slippage path but without compromising on the basic features prominent with all ROTODEL rotary pumps viz the compactness, efficiency, reliability & low noise level.

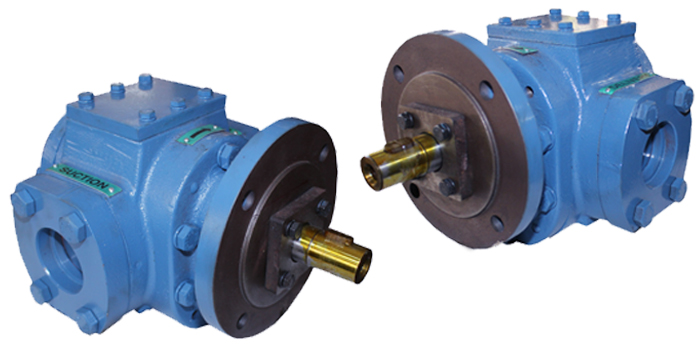

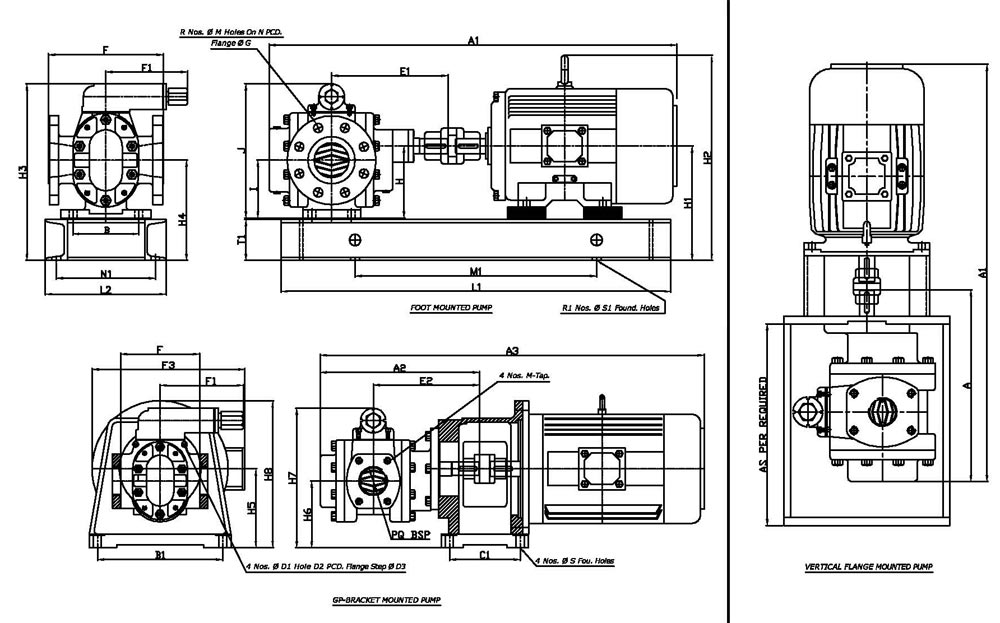

A pair of impeller with herringbone gear fitted on hardened & ground shaft with shaft sleeves in floating design supported on either side on needle/bush bearings located on end covers with ltb. wearing plate packed in between and placed inside close tolerance accurately machined casing with built in pressure relief valve makes the pump. Size 1/2″ to 2 1/2″ are provided with BSP thread inlet – oulet flange connections & they are available with foot or flange mounting. Size 3″ to 6″ are foot mounted with inlet-outlet port drilled to ASA-300 class. Type RDBX is a bush bearing version & is offered upto 2 1/2″ size.

This pump can also be offered with different MOC viz. CI,CS, Bronze, SS etc. Pump upto 35 bar are also offered in this series by further reducing the bearing span. The flange type pump coupled with flange type electric motor is offered in horizontal as well as vertical construction.

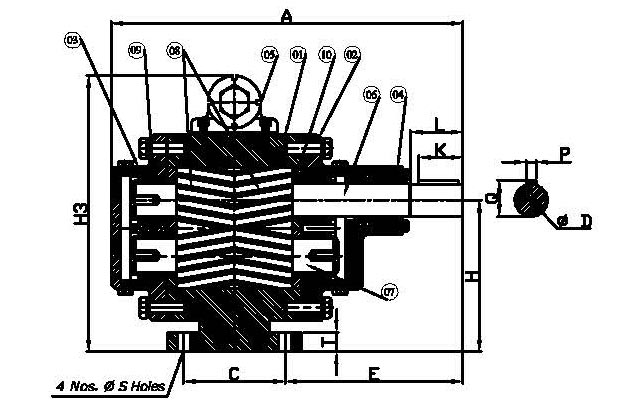

| Parts List with Material of Construction |

|||

|---|---|---|---|

| Sr. | Item | Qt | Material |

| 01 | Pump Casing | 1 | CI/CS/SS |

| 02 | Front Cover | 1 | CI/CS/SS |

| 03 | Back Cover | 1 | CI/CS/SS |

| 04 | Gland Cover | 1 | CI/CS/SS |

| 05 | R.V. Body | 1 | CI/CS/SS |

| 06 | Rotor Shaft | 1 | EN 9/19/SS |

| 07 | Stator shaft | 1 | EN 9/19/SS |

| 08 | Impeller Gear | 4 | EN 24/SS |

| 09 | Needle Brg. | 4 | IKO/INA |

| 10 | Wear Plate | 4 | LTB |

| 11 | R.V. piston | 1 | EN 8/SS |

| 12 | R.V. Spring | 1 | Spri. Steel |

| 13 | R.V. AD Screw | 1 | EN 8/SS |

| 14 | Base Plate | 1 | M.S. |

| 15 | Coup. Guard | 1 | Alumn. |

| 16 | Coupling | 1 | Flexible |

| 17 | Coup. Key | 1 | EN 8/SS |

| 18 | Sealing Sys. | 2 | OS/MS/GP |

| 19 | Dowel Pin | 4 | Silv. St |

| 20 | Comp. Flange | 2 | MS/SS |

| 21 | H/T Hex Bolt | 12 | En 8/SS |

| 22 | Inner Sleeve | 4 | En-31-57 |

| 23 | V-Seal | 4 | Nitrile.Ru. |

| 24 | Snap Ring | 1 | EN-31 |

| 25 | C.S.Screw | 3 | EN-24 |

| Available Model Size & Capacity | ||||||

|---|---|---|---|---|---|---|

| Model ‘PQ’ BSP Size |

1440 RPM Capacity | Pump GD3in KGM2 |

Elec. Motor H.P. |

FR. Size | ||

| LPM | US GPM | M3/HR | ||||

| 50 SML 1/2″ |

05.00 08.33 16.66 |

01.32 02.21 04.42 |

0.30 0.50 1.00 |

0.0001 0.0002 0.0003 |

0.50 1.00 1.50 |

71M 80M 90S |

| 100 SML 1″ |

25.00 33.32 41.65 |

06.60 08.80 11.00 |

1.50 2.00 2.50 |

0.0005 0.0005 0.0008 |

1.00 2.00 3.00 |

80M 90L 100L |

| 125 SML 1.1/4″ |

50.00 60.00 83.00 |

13.25 16.66 22.00 |

3.00 3.60 5.00 |

0.0005 0.0006 0.0008 |

2.00 3.00 5.00 |

90L 100L 112M |

| 150 SML 1.1/2″ |

100.00 125.00 150.00 |

26.50 33.00 39.75 |

6.00 7.50 9.00 |

0.0045 0.0057 0.0068 |

3.00 5.00 7.50 |

100L 112M 132S |

| 200 SML 2″ |

166.60 200.00 250.00 |

44.16 53.00 66.25 |

10.00 12.00 15.00 |

0.0068 0.0081 0.0100 |

5.00 10.00 15.00 |

112M 132M 160M |

| 250 SML 2.1/2″ |

300.00 333.00 350.00 |

79.50 88.33 92.75 |

20.00 18.00 21.00 |

0.0160 0.0174 0.0185 |

7.50 15.00 20.00 |

132S 160M 160L |

| 300 SML 3″ |

400.00 450.00 600.00 |

106.00 119.00 159.00 |

24.00 27.00 36.00 |

0.0361 0.0469 0.0560 |

25.00 30.00 35.00 |

180M 180L 200L |

| 400 SML 4″ |

700.00 800.00 900.00 |

185.50 212.00 238.50 |

42.00 48.00 54.00 |

0.0750 0.0870 0.0980 |

40.00 50.00 60.00 |

200L 225S 225M |

| 500 SML 5″ |

1000.00 1200.00 1400.00 |

265.00 318.00 371.00 |

60.00 72.00 84.00 |

0.1680 0.2800 0.2410 |

60.00 75.00 100.00 |

225M 250M 280S |

| 600 SML 6″ |

1666.00 1915.00 2082.00 |

441.50 508.00 552.00 |

100.00 115.00 125.00 |

0.3245 0.3683 0.3947 |

75.00 100.00 120.00 |

250M 280S 280M |

| Pump Motor Coding |

|---|

| Sign # Indicates Pump Size 5-short, 6-medium, 7-long |

| Sign @ Indicates Pump Type 6-RDBX, 7-RDNX |

| Model ‘PQ’ BSP Size |

Dimensions | Weight Bp-cou pump Bp-cou in Kg |

Product Code | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Overall | Mounting | Shaft | Flange | Pump | |||||||||||||||||||||

| A1 | J A |

H2 | L1 | L2 | H3 | A2 F1 H7 |

A3 F3 H8 |

B1 B S |

C1 C S1 |

E2 E1 E |

H5 F L |

H6 H I |

H1 | H4 | M1 | N1 | R1 T T1 |

ØD P Q |

K L |

ØD1 G M |

ØD1 N |

ØD3 R |

|||

| 50 SML 1/2″ |

455 505 522 |

139 206 |

235 251 225 |

425 450 475 |

140 150 180 |

143 153 162 |

196 112 175 |

460 173 180 |

125 119 8.5 |

75 40 15 |

123 133 58 |

100 100 112 |

89 71 60 |

115 124 134 |

104 113 123 |

370 405 430 |

112 112 140 |

04 15 40 |

11.5 04 13 |

22 25 |

8 Sq 65 M8 |

66 66.6 |

52 04 |

7.0 6.00 7.50 |

9D20#@ 9D20#@ 9D20#@ |

| 100 SML 1″ |

520 560 599 |

151 299 |

251 225 279 |

500 525 550 |

170 180 200 |

155 165 174 |

209 112 200 |

508 203 220 |

155 125 8.5 |

85 45 15 |

131 143 69 |

120 120 112 |

104 80 64 |

124 134 144 |

108 118 128 |

445 480 505 |

135 140 160 |

04 15 40 |

15 05 17 |

25 30 |

10 Sq 70 M8 |

83 73 |

68 04 |

10.15 11.00 13.0 |

9F20#@ 9F20#@ 9F20#@ |

| 125 SML 1.1/4″ |

591 630 658 |

185 250 |

235 289 323 |

550 600 600 |

180 200 230 |

189 195 211 |

236 141 220 |

610 245 220 |

190 155 10 |

110 50 15 |

153 168 81 |

120 135 141 |

100 90 70 |

144 154 166 |

124 134 146 |

495 545 545 |

140 160 190 |

04 15 50 |

21 06 23.5 |

30 40 |

10 Sq 80 M10 |

105 85 |

85 04 |

12.00 14.50 15.50 |

9H20#@ 9H20#@ 9H20#@ |

| 150 SML 1.1/2″ |

673 700 764 |

205 293 |

289 321 362 |

625 650 700 |

200 230 250 |

207 220 241 |

278 153 255 |

677 265 270 |

230 170 12 |

130 55 15 |

180 195 95 |

145 145 153 |

123 100 78 |

154 166 186 |

132 144 164 |

570 595 645 |

160 190 216 |

04 20 50 |

24 08 27 |

40 50 |

14 Sq 100 M12 |

125 106 |

100 04 |

15.00 24.00 18.75 |

9J20#@ 9J20#@ 9J20#@ |

| 200 SML 2″ |

746 850 950 |

234 339 |

338 377 435 |

700 825 900 |

230 250 285 |

238 258 286 |

338 173 315 |

762 285 340 |

290 200 12 |

180 70 19 |

222 223 94 |

190 165 173 |

164 112 86 |

181 205 229 |

155 175 203 |

630 755 830 |

190 216 230 |

04 20 65 |

27 08 30 |

40 55 |

14 Sq 120 M12 |

140 127 |

115 04 |

18.00 35.00 21.00 |

9K20#@ 9K20#@ 9K20#@ |

| 250 SML 2.1/2″ |

850 990 1030 |

261 375 |

287 445 445 |

800 900 950 |

260 315 315 |

266 294 294 |

355 173 320 |

882 325 340 |

290 225 15 |

180 80 19 |

223 250 104 |

190 190 173 |

161 132 103 |

211 239 239 |

182 210 210 |

550 650 700 |

200 254 254 |

04 25 75 |

32 10 35 |

50 60 |

14 Sq 135 M14 |

152 149 |

125 04 |

19.00 55.00 23.00 |

9L20#@ 9L20#@ 9L20#@ |

| 300 SML 3″ |

1165 1165 1235 |

338 436 |

568 568 616 |

1150 1150 1200 |

330 330 355 |

342 342 362 |

205 | 180 19 |

90 19 |

289 244 |

280 205 |

180 146 |

284 284 304 |

250 250 270 |

850 850 900 |

279 279 318 |

04 25 100 |

37 10 40 |

55 65 |

210 22 |

168 | 08 | 33.00 73.00 37.00 |

9M20#@ 9M20#@ 9M20#@ |

|

| 400 SML 4″ |

1285 1330 1360 |

375 487 |

616 666 666 |

1300 1400 1400 |

370 406 406 |

379 404 404 |

230 | 180 19 |

130 22 |

323 258 |

300 230 |

200 160 |

304 329 329 |

264 289 289 |

900 900 900 |

318 356 356 |

04 28 100 |

47 14 50.5 |

70 80 |

254 22 |

200 | 08 | 52.00 92.00 58.00 |

9N20#@ 9N20#@ 9N20#@ |

|

| 500 SML 5″ |

1405 1495 1590 |

420 533 |

691 794 854 |

1450 1550 1600 |

430 470 520 |

424 449 479 |

230 | 200 22 |

150 22 |

346 271 |

340 230 |

225 179 |

354 379 409 |

308 333 363 |

1050 1050 1150 |

356 406 457 |

04 28 150 |

52 16 56 |

75 85 |

279 22 |

235 | 08 | 52.00 142.00 76.00 |

9P20#@ 9P20#@ 9P20#@ |

|

| 600 SML 6″ |

1510 1610 1610 |

467 550 |

819 879 879 |

1650 1700 1700 |

470 520 520 |

471 501 501 |

245 | 215 22 |

170 22 |

358 293 |

345 245 |

250 200 |

404 434 434 |

354 384 384 |

1150 1150 1150 |

406 457 457 |

04 28 150 |

57 16 61 |

80 95 |

317 22 |

270 | 12 | 78.00 173.00 85.00 |

9R20#@ 9R20#@ 9R20#@ |

|

Pump Operation & Performance Characteristics

Gear pump is the most versatile rotary positive displacement pump & it scores over other types of Pd pumps viz. Screw, Vane, Lobe, Tracoidal, Radial piston etc. & therefore it is used for the widest range of application i.e. loading-unloading, transfer, fuel pressurizing, hydraulic, lubrication in IC engines, Polymers metering applications etc. Gear pump can develop high pressure uo tp 210 bar in same configuration simply by tightening the working clearances & improving the workmanship, whereas in screw pump the thread length is needed to increase making the pump bulky & difficult to manufacture. In gear pump each tooth gap contributes to the capacity while in screw pump only one pitch length contributes to the capacity thus gear pumps are always cpmpact & efficient. The capacity of the pump varies directly with speed but remain constant against pressure, however some liquid always by-passes to suction due to running clearance between the casing & impeller causing slip which depends upon the differential pressure, viscosity of the liquid & the workmanship. Gear pumps are capable of handling liquids of any viscosity, th slip reduces with increse in viscocity but the frictional power increses. Though the pump has a self priming capability some net positive suction head(NPSH) is always required to avoid cavitation, this again depends on the viscosity of the liquid to be pumped & the pumping speed.

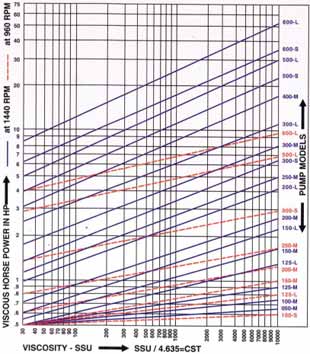

Internal power losses

In rotary gear pumps are of two types.The mechanical loss is the power required to overcome friction drag of all the moving part within the pump while viscous loss is power loss due to fluid viscous drag & shearing action of the fluid, this can be calculated from the graph shown here.

Horse power calculation

The bhp required to drive a rotary pump is sum of the theoretical HP & internal losses. The former is the actual work done in moving the fluid from inlet pressure condition to outlet pressure condition & is product of constant C=0.037, Capacity in M3/hr. & Pressure in Kg/CM2 or Constant c-2.3, Capacity in GPM & Pressure in PSI.

Gear Pump Selection & uses

RDBX/NX series pump are medium pressure pumps designed for viscous pressure application up to 21 bar. The bush bearing version type RDBX is used for clean or dirty viscous & semi viscous liquid where the shaft surface speed is less. Pump upto 21/2″ size can be run at 1440 RPM & for higher size the speed should be reduced to 960 RPM or lower. The self-lubricated needle roller bearing type can be used for clear viscous liquid & can be run at 1440 RPM for all the sizes. This pump are ideally suited for fuel pressuring, hydraulic, medium pressure lubrication & transfer applications.

Inspection & testing

All pumps are assembled after due inspection of each & every parts & than they are tested for duty parameters in accordance with API-676 & JIS-B 8312-1976. Third party inspection are also offered, we are approved by following consultants & inspection agencies.