Description

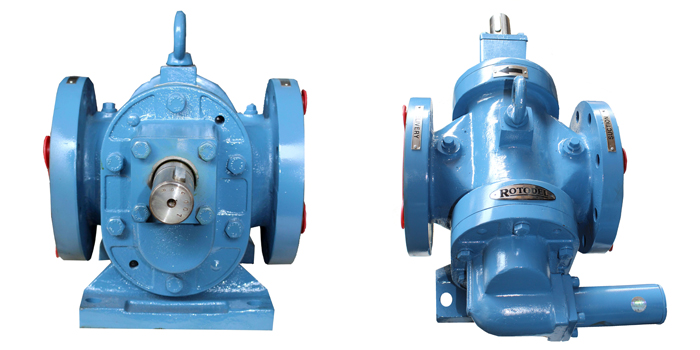

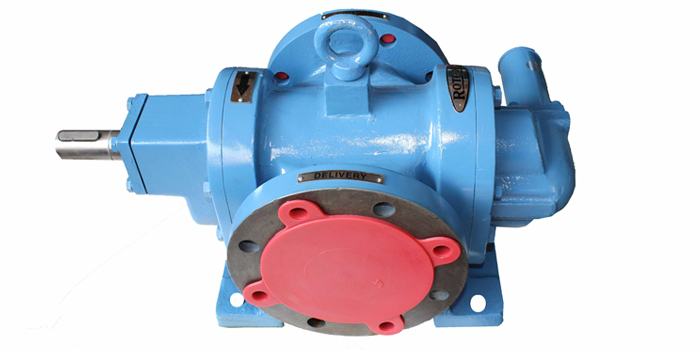

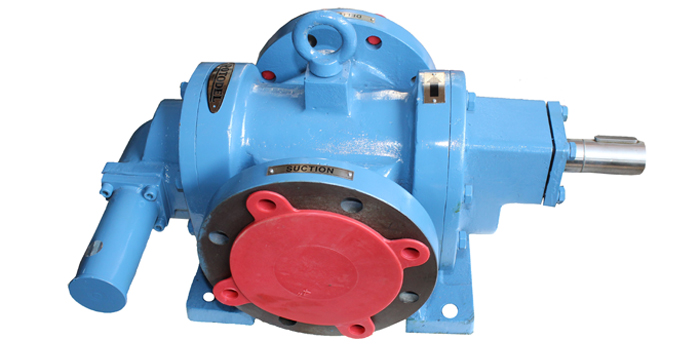

Proven Performance & Operational economy are prime consideration while evaluting your pumping requirement. When it comes to handling viscous or semiviscous liquirds, ‘ROTODEL’ rotary gear pump is an obvious choice for the very reasons.

‘ROTODEL’ rotary gear, twin gear & screw-gear pumps are welknown, widely accepted pd pumps in all th industries for it’s efficient performance, operational reliability, compact design & noiseless operation. These pumps have outclassed convenational gear pump & has also broken myth about screw pump offering better overall performance at considerable reduced cost.Many imported gear & screw pumps are replaced with ‘ROTODEL’ pumps in power stations, steel plants, refineries, oil installation on navy vessels & cargo ships.

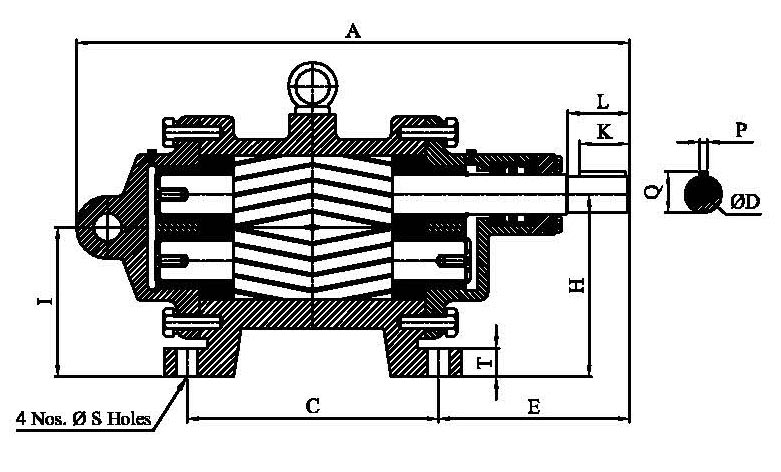

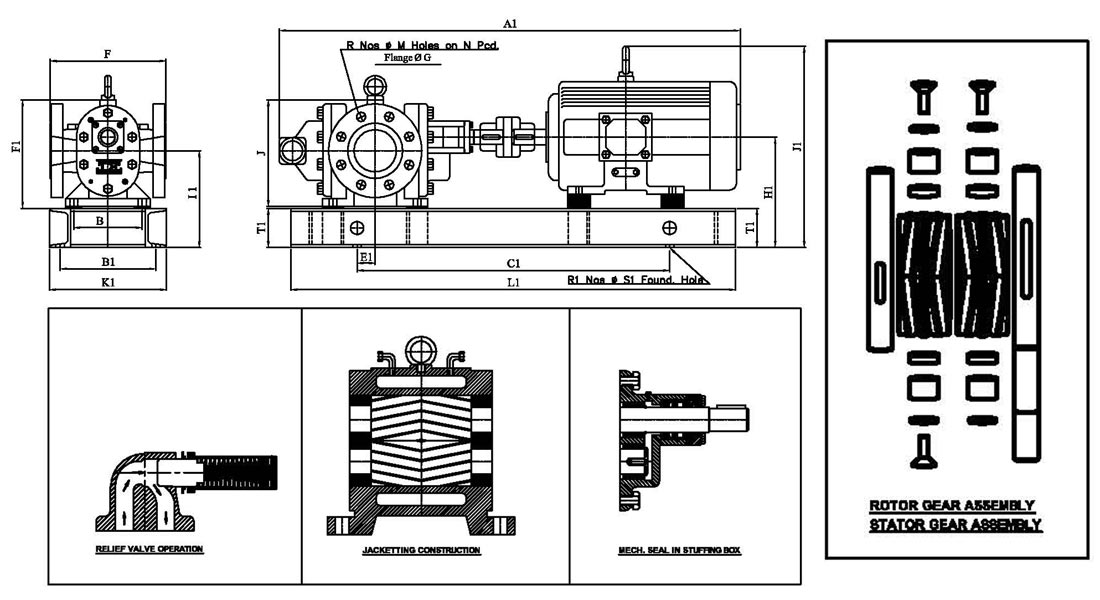

Popular range of ‘RDNXJ’ series `ROTODEL’ rotary screw-gear pumps are re-designed & re-engineered to offer further simplicity with added reliability meeting international standard like API, JIS, DIN & above all, the growing expectations of enlightened customers. New ‘RDRN’ series twin gear pump now offers enlarged capacity range with option of self or independently lubricated jacketed or non-jacketed construction with all sizes designed to run at synchronous speed of 4-pole primemover to further reduce the overall cost of the pump set..

It will be a wise decision to go for `ROTODEL’ rotary twin gear pump even If it amounts to scrapping exisiting Pump at your present installation.

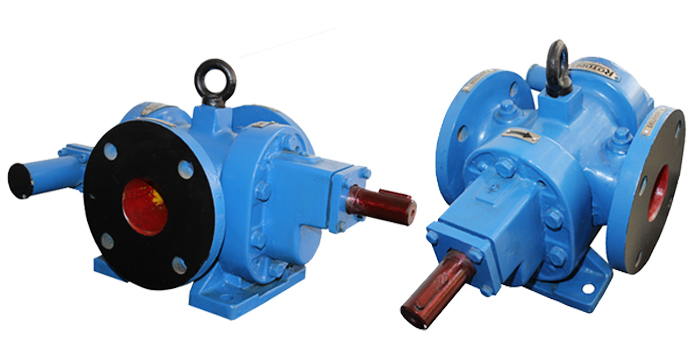

Advantages

- Herrigbone rotos design eliminates side thruts.

- Modified tooth profile enhances the tooth life.

- Floating gear-design ensures uniform load distribution.

- Low-leakage path by design improve volumetric efficiency.

- Extra thick shaft reduces bending effectively.

- Sleeve on shaft make maintenance economical & easy.

| Parts List with Material of Construction |

|||

|---|---|---|---|

| Sr. | Item | Qt | Material |

| 01 | Pump Casing | 1 | CI/CS/SS |

| 02 | Front Cover | 1 | CI/CS/SS |

| 03 | Back Cover | 1 | CI/CS/SS |

| 04 | Gland Cover | 1 | CI/CS/SS |

| 05 | Rotor Shaft | 1 | EN 9/19/SS |

| 06 | Stator shaft | 1 | EN 9/19/SS |

| 07 | Impeller Gear | 4 | EN 24/SS |

| 08 | Needle Brg. | 4 | IKO/INA |

| 09 | Wear Plate | 4 | Bronze |

| 10 | Lifting Hook | 1 | Steel |

| 11 | R.V. Housing | 1 | Mal.Iron |

| 12 | R.V. Piston | 1 | EN 8/SS |

| 13 | R.V. Spring | 1 | Spri. Steel |

| 14 | R.V.AD Screw | 1 | EN 8/SS |

| 15 | Base Plate | 1 | M.S. |

| 16 | Coup. Guard | 1 | Alumn. |

| 17 | Coupling | 1 | Flexible |

| 18 | Coup. Key | 1 | EN 8/SS |

| 19 | Sealing Sys. | 2 | OS/MS/GP |

| 20 | Dowel Pin | 4 | Silv. St |

| 21 | Comp. Flange | 2 | MS/SS |

| 22 | H/T Hex Bolt | 12 | En 8/SS |

| Available Model Size & Capacity | ||||||

|---|---|---|---|---|---|---|

| Size & Model |

1440 RPM Capacity | Pump GD2in KGM2 |

Elec. Motor H.P. |

FR. Size | ||

| LPM | US GPM | M3/HR | ||||

| 1/2″ 50 SML |

8.30 16.60 25.00 |

02.20 04.40 06.60 |

0.50 1.00 1.50 |

0.0008 0.0009 0.0010 |

0.50 0.75 1.00 |

71M 80M 80M |

| 1″ 100 SML |

33.30 50.00 60.00 |

08.80 13.20 15.84 |

2.00 3.00 3.60 |

0.0007 0.0008 0.0009 |

0.75 1.00 2.00 |

80M 80M 90L |

| 1.1/2″ 150 SML |

83.30 100.00 125.00 |

22.00 26.40 33.30 |

5.00 6.00 7.50 |

0.0008 0.0008 0.0032 |

2.00 3 5.00 |

90L 100L 112M |

| 2″ 200 SML |

150.00 166.00 200.00 |

39.00 44.00 52.80 |

9.00 10.00 12.00 |

0.0068 0.0074 0.008 |

3 5.00 7.50 |

100L 112M 132S |

| 2.1/2″ 250 SML |

250.00 299.88 333.30 |

66.00 79.20 88.00 |

15.00 18.00 20.. |

0.01 0.013 0.015 |

5.00 7.50 10.00 |

112M 132S 132M |

| 3″ 300 SML |

415.00 449.82 500.00 |

105.00 118.00 132.00 |

25.00 27.00 30.00 |

0.02 0.024 0.027 |

10.00 12.50 15.00 |

132M 160M 160M |

| 4″ 400 SML |

599.76 666.66 833.30 |

158.40 176.00 220.00 |

36.00 40.00 50.00 |

0.056 0.062 0.072 |

15 20 25.00 |

160M 160L 180M |

| 5″ 500 SML |

1000.00 1250.00 1499.00 |

264.00 330.00 396.00 |

60.00 75.00 90.00 |

0.098 0.112 0.177 |

20 30.00 40.00 |

160L 180L 200L |

| 6″ 600 SML |

1660.00 1832.60 2083.00 |

440.00 484.00 550.00 |

100.00 110.00 125.00 |

0.27 0.31 0.335 |

30.00 50.00 60.00 |

180L 225S 225M |

| 6″ 600 SML |

2499.00 2915.50 3332.00 |

660.00 770.00 880.00 |

150.00 175.00 200.00 |

0.4561 0.542 0.601 |

50 75.00 100.00 |

225S 250M 280S |

| Pump Motor Coding |

|---|

| Sign # Indicates Pump Size 5-short, 6-medium, 7-long |

| Sign @ Indicates Pump Type 0-RDRB, 1-RDRBJ, 2-RDRN, 3-RDRNJ, 4-RDRX, 5-RDRXJ |

| Sign * Indicates Motor Type W-NON-Flame Proof X-Flame proof motor |

| Size & Model |

Dimensions | Weight Bp-cou pump Bp-cou in Kg |

||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Overall | Mounting | Shaft | Flange | |||||||||||||||||||

| A1 | J A |

J1 | L1 | K1 | F1 | B C |

S S1 |

E F |

H I |

H1 | T1 T |

E1 | C1 | B1 | I1 | D R1 |

K L |

P Q |

M N |

G R |

||

| 1/2″ 50 SML |

503 538 538 |

122 239 |

262 283 283 |

500 525 525 |

145 170 170 |

125 130 130 |

80 100 |

8 15 |

91 150 |

80 69 |

158 163 163 |

75 10 |

37 36 36 |

340 365 365 |

112 125 125 |

147 152 152 |

11.5 4 |

22 30 |

4 13 |

16 60 |

89 4 |

11.5 8.00 12.00 |

| 1″ 100 SML |

570 570 620 |

136 271 |

288 288 315 |

600 600 650 |

145 145 180 |

139 139 146 |

90 110 |

10 15 |

100 160 |

90 74 |

168 168 175 |

75 10 |

26 26 26 |

360 360 410 |

120 120 140 |

151 152 159 |

15 4 |

25 30 |

5 17 |

16 79 |

108 4 |

12.2 14.0 13.1 |

| 1.1/2″ 150 SML |

667 697 742 |

160 318 |

320 328 353 |

625 750 750 |

165 205 230 |

165 163 175 |

105 130 |

10 15 |

119 180 |

100 80 |

180 178 190 |

75 12 |

3 30 26 |

375 500 500 |

130 170 190 |

160 158 170 |

21 4 |

25 40 |

6 23.5 |

16 98 |

127 4 |

14.0 22.5 18.00 |

| 2″ 200 SML |

738 783 853 |

174 359 |

340 353 398 |

775 800 800 |

210 230 256 |

177 177 197 |

110 150 |

12 15 |

133 200 |

112 90 |

190 190 210 |

75 14 |

50 65 50 |

525 550 600 |

170 190 216 |

168 168 188 |

24 4 |

39 50 |

8 27 |

19 121 |

152 4 |

17.5 28.00 20.8 |

| 2.1/2″ 250 SML |

842 913 953 |

200 419 |

377 398 398 |

800 900 950 |

249 255 255 |

203 203 203 |

130 160 |

15 15 |

163 220 |

132 106 |

204 210 210 |

75 15 |

35 50 50 |

550 650 700 |

205 216 216 |

184 184 184 |

27 4 |

40 55 |

8 30 |

19 140 |

178 4 |

18.5 43.00 22.5 |

| 3″ 300 SML |

1015 1113 1113 |

240 481 |

451 528 528 |

1050 1100 1100 |

287 304 304 |

243 243 243 |

160 220 |

18 19 |

168 240 |

160 131 |

263 263 263 |

100 22 |

84 75 75 |

750 800 800 |

240 254 254 |

234 234 234 |

32 4 |

49 60 |

10 35 |

19 152 |

190 4 |

22.0 59.00 33.00 |

| 4″ 400 SML |

1186 1231 1296 |

274 554 |

548 548 568 |

1200 1250 1300 |

315 310 330 |

277 277 277 |

180 270 |

18 19 |

189 280 |

180 145 |

283 283 283 |

100 25 |

58 58 90 |

800 900 900 |

265 254 279 |

248 248 248 |

37 4 |

54 65 |

10 40 |

19 190 |

229 8 |

40.0 82.0 47.2 |

| 5″ 500 SML |

1292 1357 1447 |

293 615 |

603 313 673 |

1350 1400 1400 |

300 365 380 |

306 296 296 |

200 280 |

19 22 |

215 300 |

200 160 |

338 328 328 |

125 25 |

55 125 116 |

950 1000 1000 |

254 300 318 |

298 288 288 |

47 4 |

60 85 |

14 50.5 |

22 216 |

254 8 |

58.0 150.0 50.5 |

| 6″ 600 SML |

1432 1608 1608 |

343 690 |

643 728 728 |

1500 1650 1650 |

305 420 420 |

351 346 346 |

220 350 |

20 22 |

215 340 |

225 178 |

358 353 353 |

150 25 |

183 137 137 |

1100 1150 1150 |

245 356 356 |

311 306 306 |

52 4 |

80 95 |

16 56 |

22 241 |

279 8 |

50.5 175.0 76.0 |

| 6″ 600 SML |

1667 1882 1882 |

357 749 |

778 853 853 |

1650 1800 1850 |

430 480 530 |

360 406 390 |

380 240 |

22 22 |

230 360 |

250 200 |

403 433 433 |

150 28 |

136 126 126 |

1150 1350 1350 |

356 457 457 |

353 383 383 |

57 4 |

81 100 |

16 59 |

22 241 |

279 8 |

77.7 190.0 87.00 |

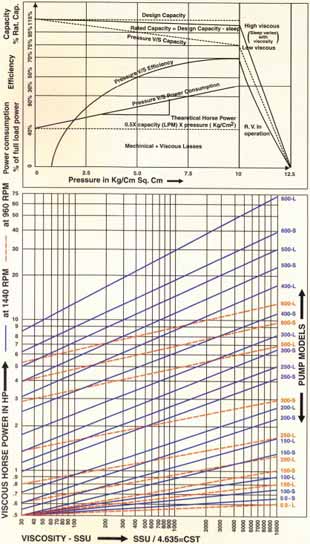

Pump Characteristics

Gear pump is a rotary positive displacement pump with positive pressure characteristics. The capacity of the pump varies directly with speed but remain constant against pressure, however due to running clearance between the casing & impeller some liquid always by-passes to suction causing sleep, which depends upon the differential pressure, viscosity of the liquid & ofcourse the workmanship. The pumps are capable of handling any vcosity, the sleep reduces with viscosity but the viscous power increases. The punp has a self-priming capability however some net positive suction head (NPSH) is always required to avoid cavitations depending upon the viscosity of the liquid to be pumped & the pump speed.

Internal power losses

The internal power losses in rotary pumps are of two types. The mechanical losses is the power necessary to overcome frictional drag of all the moving part within the pump While viscous losses is power requited to overcome fluid viscous drag & shearing action of the fluid, this can be computed from the graph on the opposite side.

H.P. calculation

The break horse power required to drive a rotary pump is sum of the theoretical HP & internal losses. The theoratical power is the actual work done in moving the fluid from inlet port to out let pressure condition & is product of Constant C=0.037, Capacity in cub. Mt./hr. & Pressure Kg/Sq. Cm or Constant=2.39, Capacity in us GPM & Pressure in PSI.

Pump Selection & uses

The bush bearing type of pump can be used for clean viscous liquid having sufficient lubricating value such as clean tube oil, Vegitable oil, Fish & Animal oil, Gear oil, Glycerine Hydraulic oil, Honey,ASMI & SAE lubricating oil for intermittant duty. However for continues duty pump with needle roller bearing in ‘RDRN’ series should be selected. For liquid having low viscosity,poor lubricating values or Containing dirts or impurities such as Crude oil, Dirty lube oil, HSD,Kerosene,LDO,Paints, Sugar solution, Turpentine, Varnish, WoodPulp. Pump with independently lubricated bearing should be selected. For liquid which tends to solidify at room temperature such as Ashphalt, Bituman, Fumace oil, Tar, Cellulose, Starch, LSHS, HPS, Molasses, Naptha, Phenol resin, RFO, Silicate, Soap solution,Viscous,Wax etc. Jacketing constructions hould be selected to facilitate the heating or the pump by steam or thermic fluid.

Inspection & testing

All Pumps are individialy tested for its performance as per JIS B-8312-1976. Third party inspection is also offered to following agencies with whom we are already registesed as an approved supplier of these pumps.